Discovering Unlimited Potential: Interpreting the Core Values of Supporting Material 111

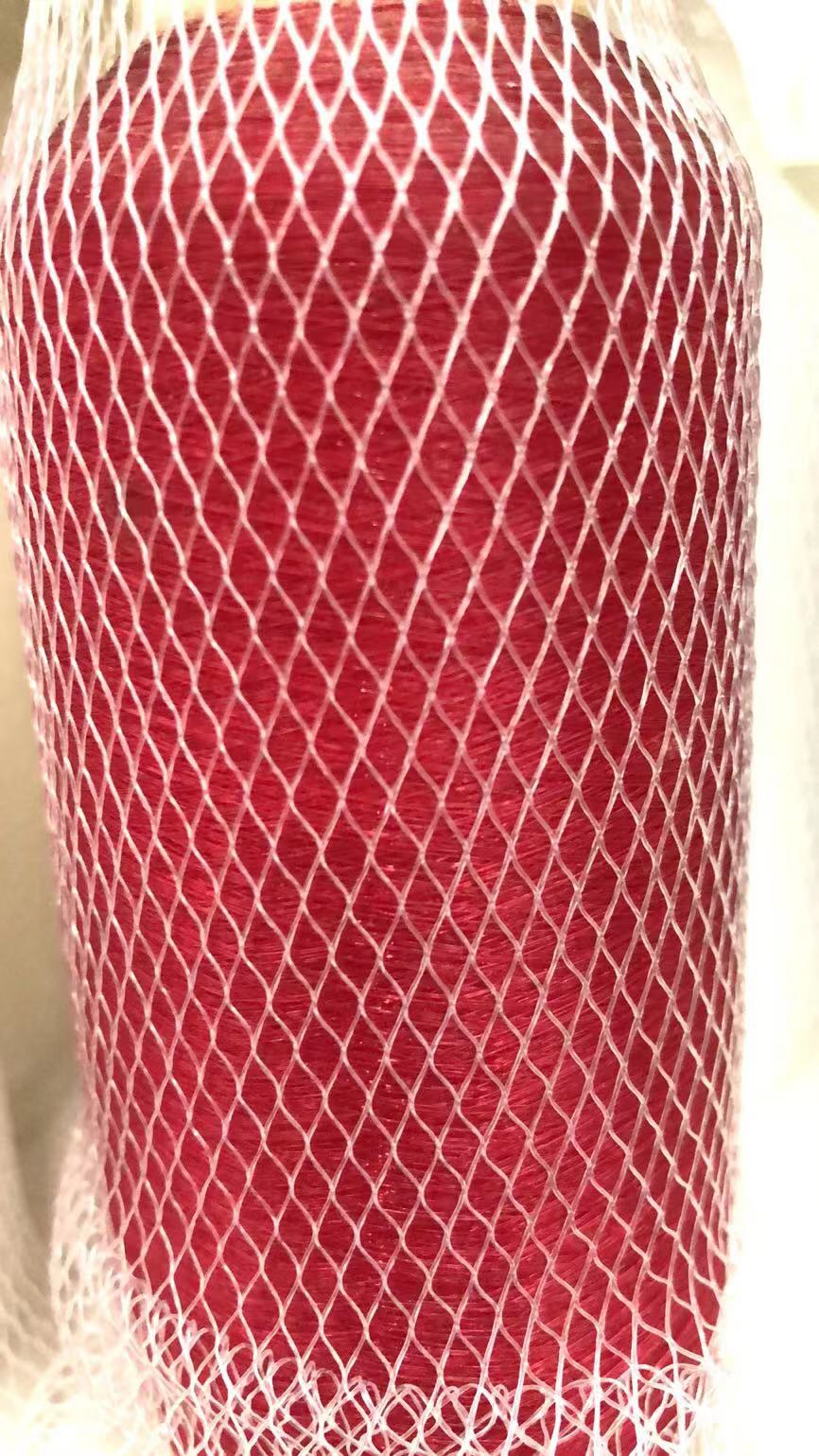

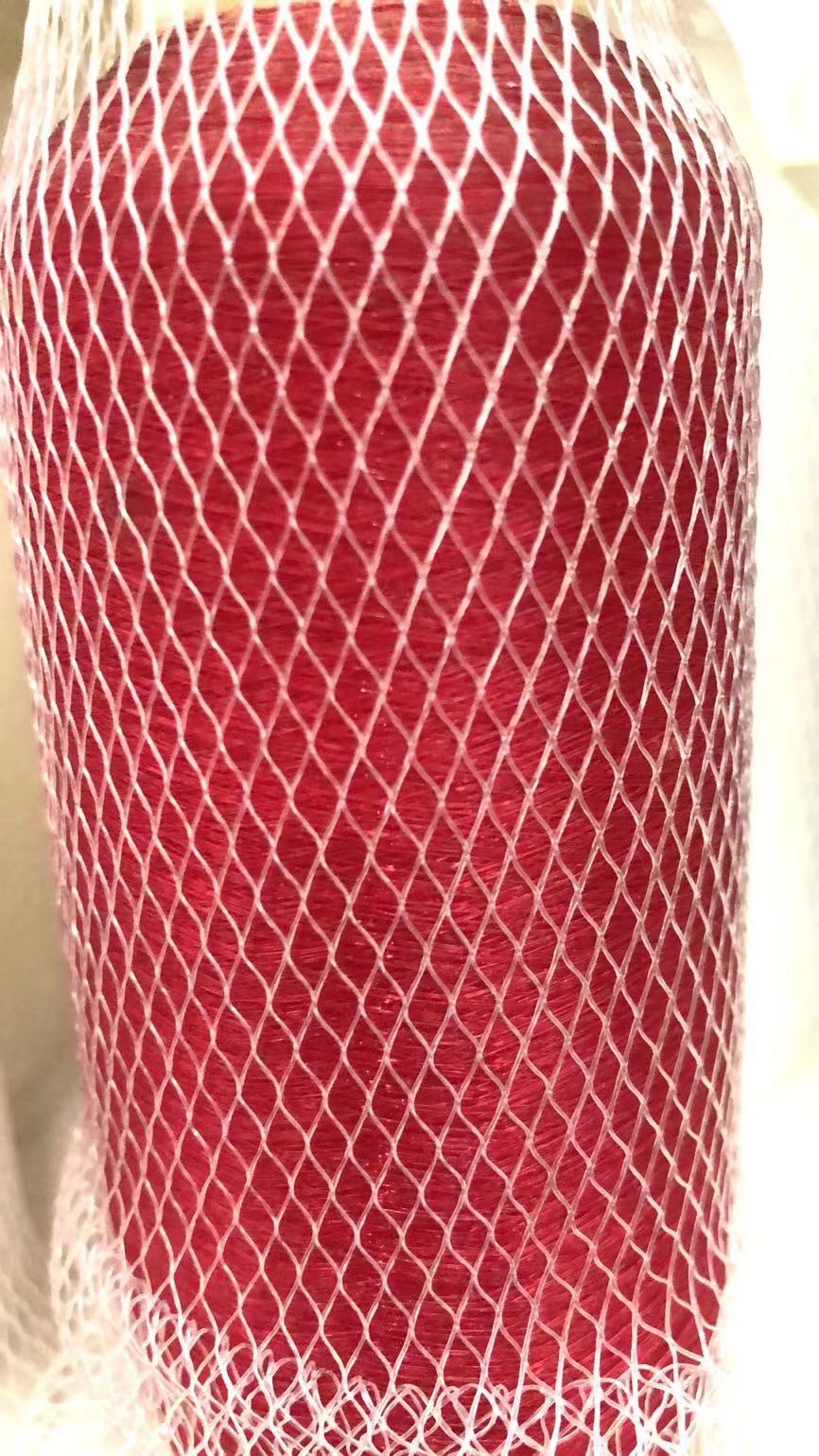

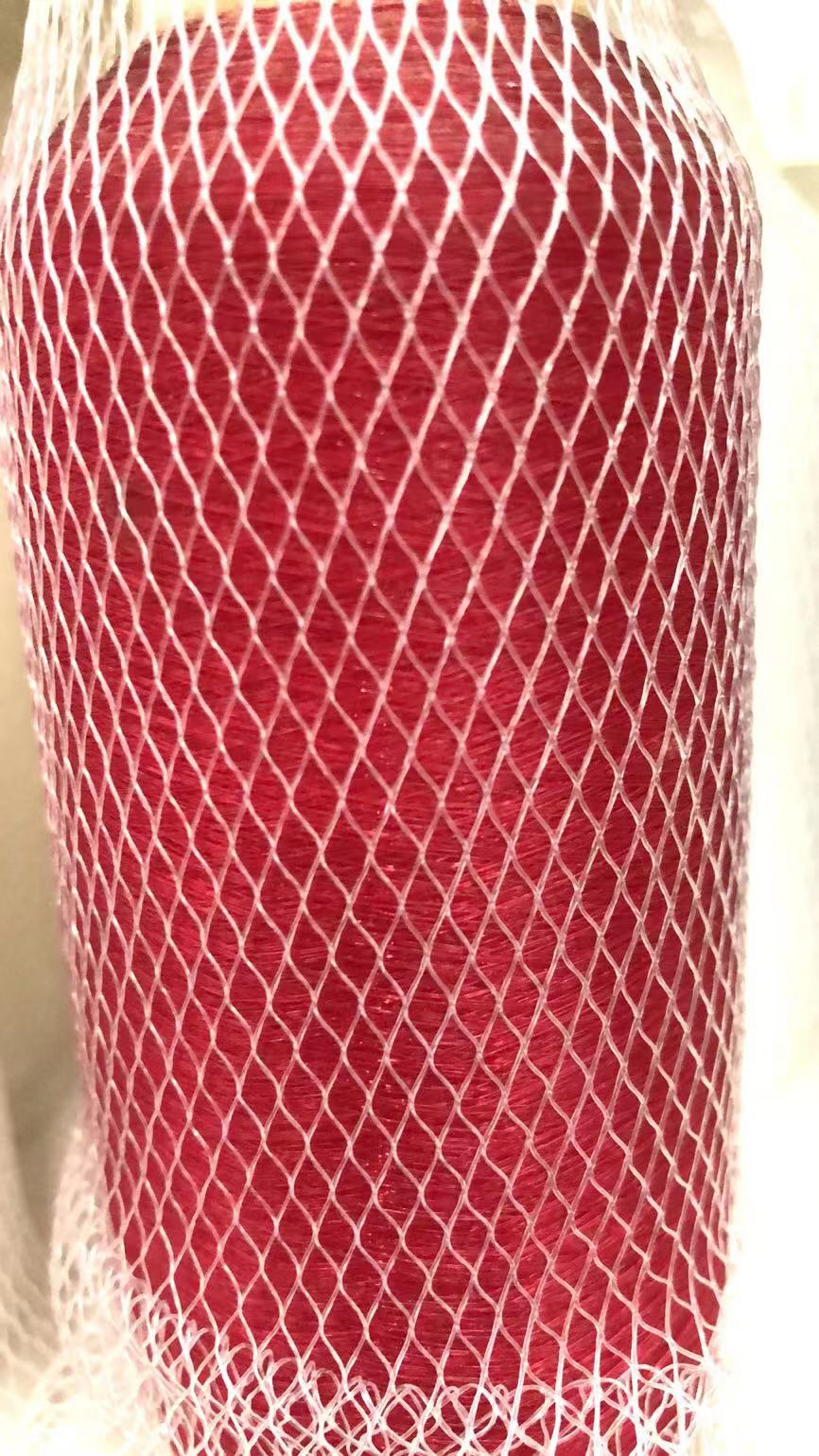

From construction to manufacturing to everyday life, supporting materials 111 is becoming an integral part of all walks of life. We will explore how the product's unique features-both its physical and chemical properties-stand out from the competition and provide unprecedented support and convenience for businesses and individuals.

Whether it maintains stable mechanical strength under extreme conditions, or exhibits excellent corrosion and wear resistance, the auxiliary material 111 has demonstrated performance beyond regular. These characteristics not only make it adapt to the complex construction environment, but also bring more possibilities in daily life. For example, in a home repair project, it can quickly repair damaged objects without leaving traces; in outdoor activities, it can withstand the effects of bad weather and extend the service life of items.

Breaking Traditional Boundaries: The Secret Weapon Behind Multifunctional Uses

Understand the reasons why auxiliary material 111 can be widely used in many industries. Through specific case analysis, it shows its flexible application in different scenarios, including but not limited to industrial production, construction engineering, home decoration and other fields. Behind each application, there is precise technical support and innovative ideas, which makes this product truly achieve the goal of "one material with multiple uses.

In a large bridge construction project, engineers used new composite materials instead of traditional concrete reinforcement. Because this new material has higher tensile resistance and seismic performance, it greatly reduces engineering costs and time consumption. The same reason has also been introduced into the residential decoration market, consumers can choose to use environmentally friendly sealant instead of ordinary silicone rubber for doors and windows installation, both beautiful and generous and can effectively prevent leakage. All this is due to the ingenious transformation of the molecular structure of raw materials by R & D personnel, so as to develop more diversified and more targeted functional modules.

Technology Innovation Drives the Future: An In-Depth Analysis of Advanced Processes and Formulations

What gives the auxiliary material 111 such a powerful performance? The answer lies in the R & D team's continuous pursuit of scientific and technological progress. The novel techniques and unique formulations used to produce the material are described in detail here, such as the use of nanoscale additives and the selection of environmentally friendly degradable ingredients. These innovative elements not only improve the quality of products, but also actively respond to the call of modern society for sustainable development.

Advances in nanotechnology have injected new vitality into materials science, especially in enhancing toughness. Scientists refine the micron-level particles to tens or even tens of nanometers and mix them into the matrix resin to form a uniform distribution state, which can greatly improve the overall stiffness level and does not affect the existence of other excellent properties. In addition, it is worth mentioning that with the increasing awareness of environmental protection, green and ecological friendly raw materials have been paid more and more attention. Therefore, in the latest version of the research and development results, bio-based polymers and natural cellulose derivatives are specially added as plasticizers to replace petroleum chemicals, so as to achieve the purpose of reducing carbon emissions.

Data Talk: Empirical Research Verifies Excellence

While theoretical superiority is important, practical results are the key. Through the comparative analysis of a series of laboratory test reports and field use data, it is proved that the auxiliary material 111 has achieved excellent results in all aspects. We will also cite the recognition certificates or awards given by some professional institutions to further consolidate readers' confidence in their reliability.

The experimental data show that after running continuously for more than 1,000 hours in a high temperature and high humidity environment, the sample still maintains the original hardness value unchanged. However, there are no signs of cracks or other forms of damage in the low temperature impact test. In addition, the relevant conformity mark (ISO9001) issued by the third-party certification center indicates that the enterprise has established a perfect quality management system and strictly implements the operation standard process to ensure that the factory batch can meet the expected index requirements.

The Power of User Testimony: Hear the Inspiration of Success Stories

Real customer feedback is often the strongest evidence. The personal experiences of several typical users were selected to describe how they used the auxiliary material 111 to solve problems in their work or improve their quality of life. Through these vivid stories, we can feel that the changes brought about by this product are not only changes on the material level, but also changes in spiritual attitude.

Mr. Zhang is a quality manager of a well-known automobile manufacturer. He found that the connection between some parts in the production line was not tight enough, which led to a decline in the yield. Later, after trying to replace the modified plastic pipe joint assembly containing a specific proportion of filler, the problem was solved, which not only improved the assembly efficiency but also reduced the probability of waste generation. Ms. Li is an interior designer. She likes to challenge novel and unique design solutions but she can't find them.