Reveal the mystery of auxiliary material 111

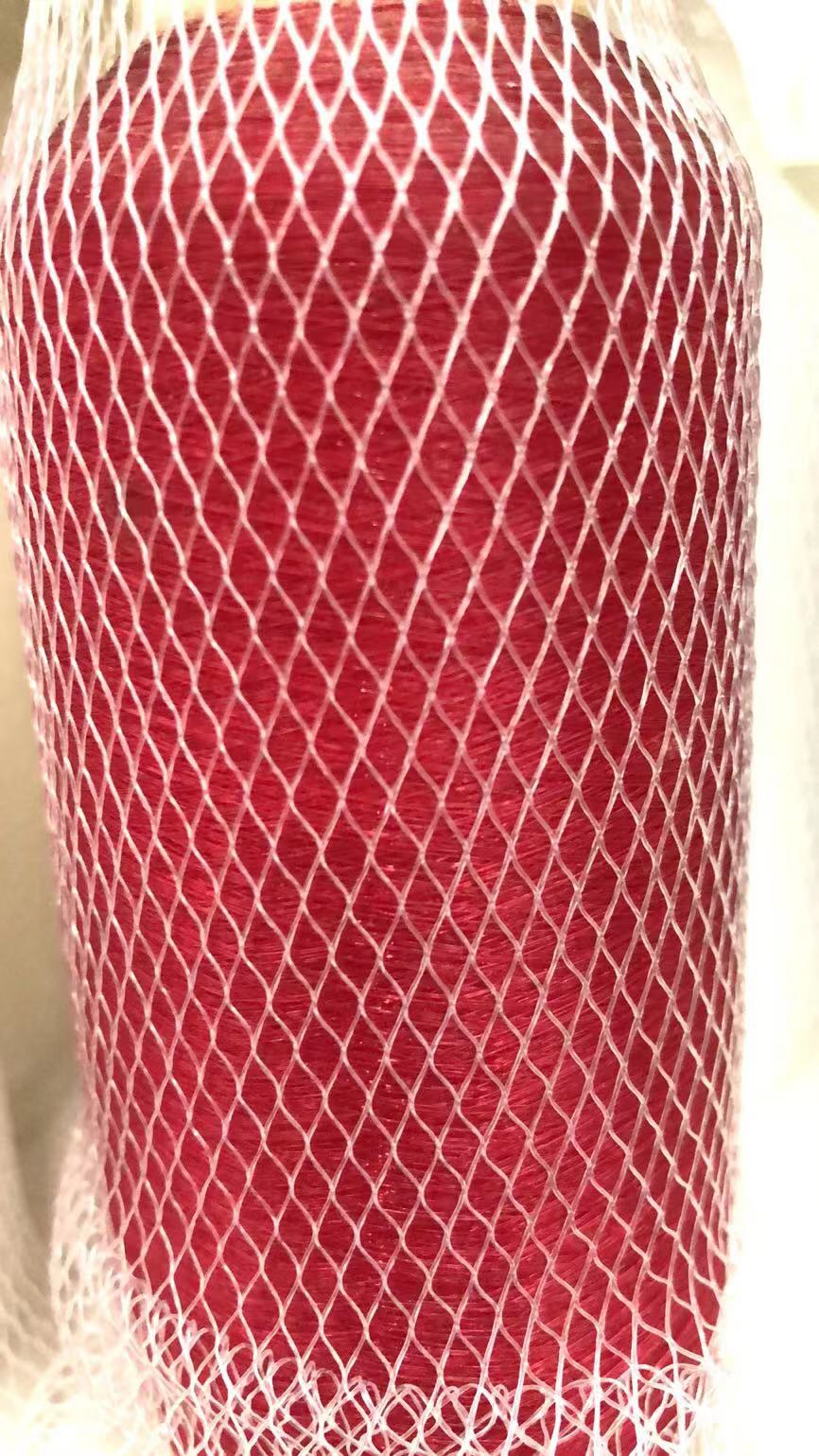

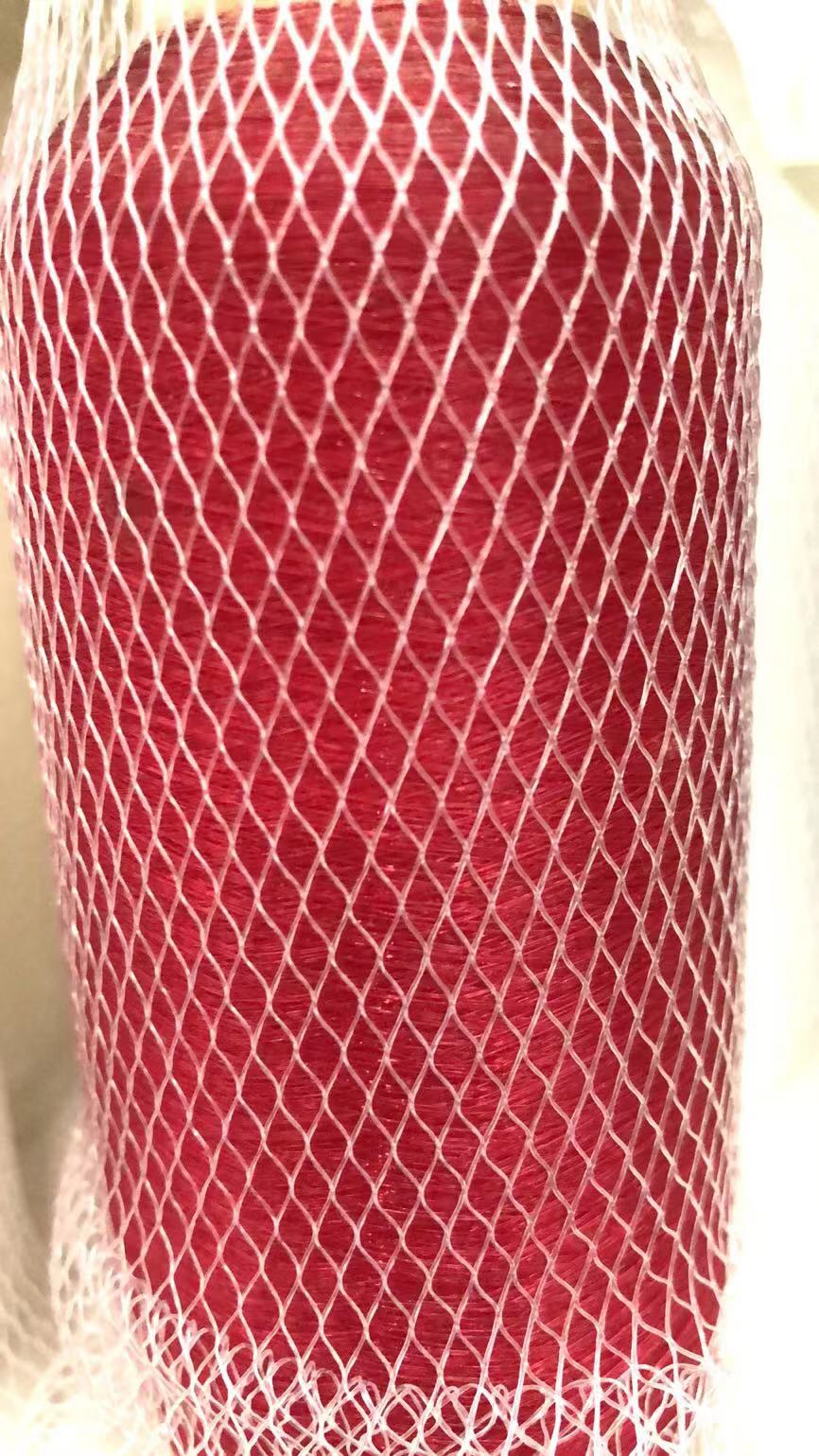

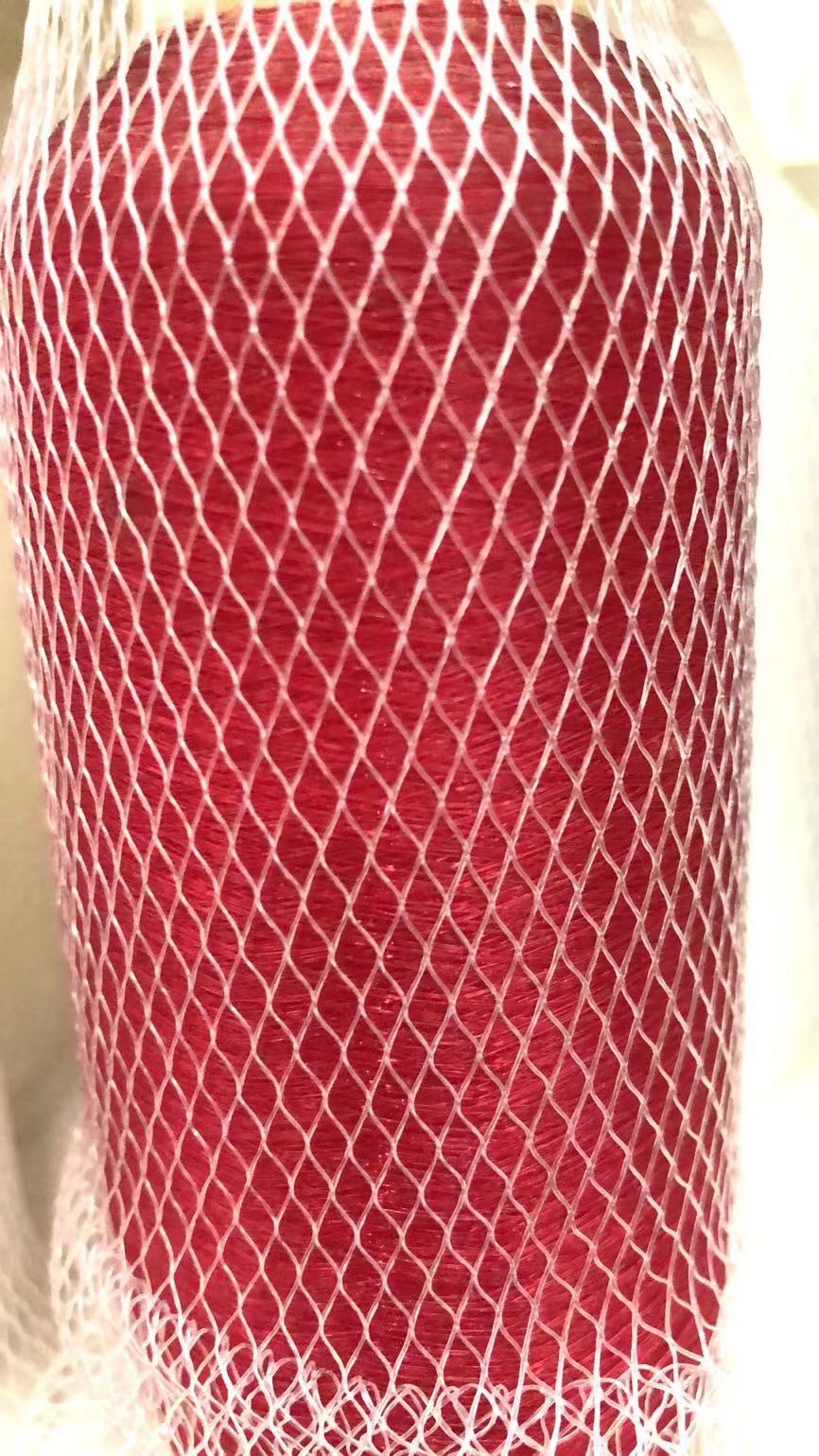

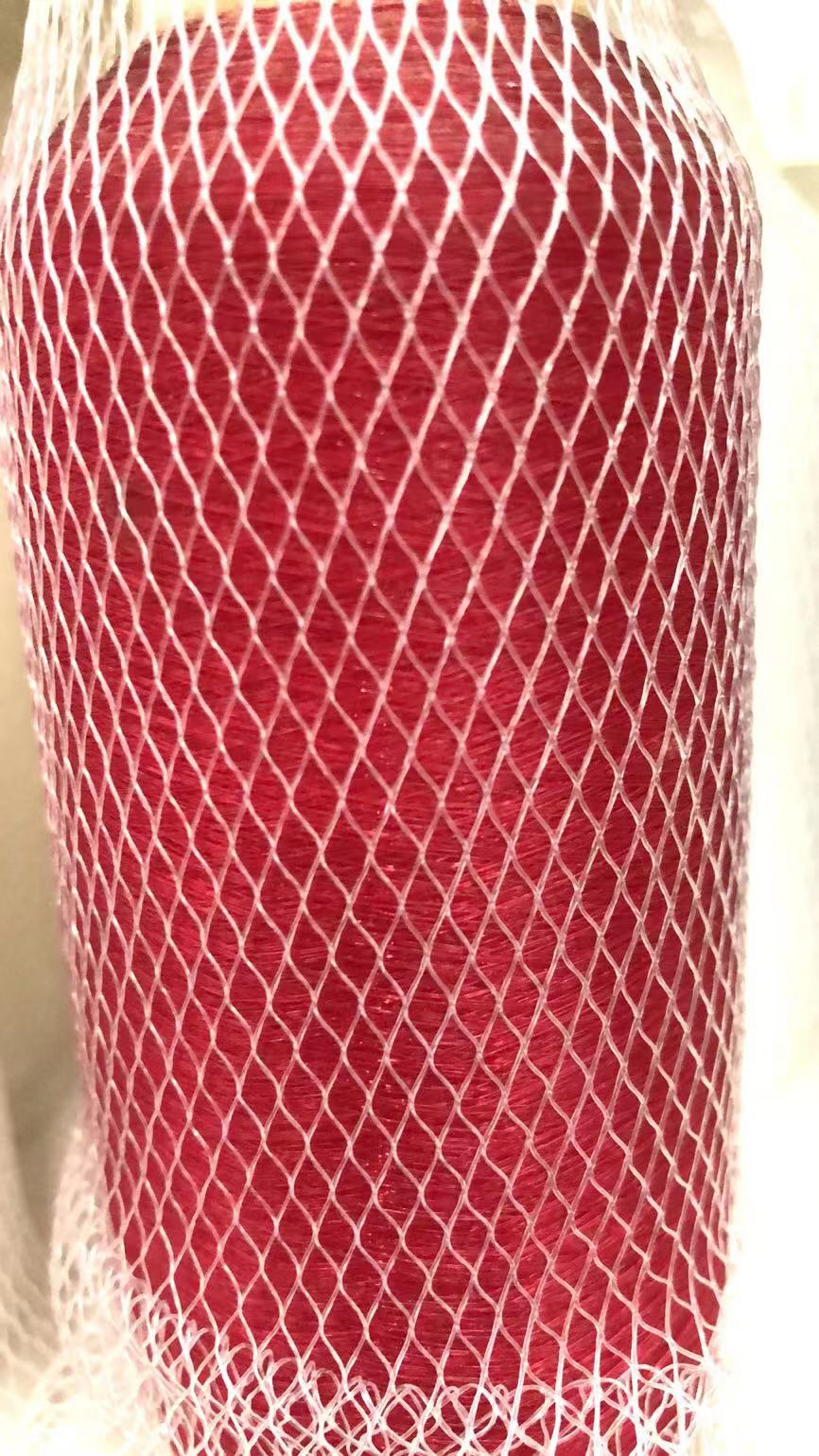

Among the many auxiliary materials, the auxiliary material 111 has attracted much attention because of its unique properties. This material is a composite of a variety of high-strength fibers with excellent physical properties and chemical stability. It has moderate density, extremely high strength, corrosion resistance and wear resistance, and is suitable for extreme environmental conditions. In addition, the auxiliary material 111 also has excellent insulation properties and can play an important role in electrical engineering.

It is precisely because of these characteristics that the auxiliary material 111 can stand out among many materials and become a sharp weapon in the hands of professionals. Whether it is reinforcement work on a construction site or the assembly of precision electronic equipment, auxiliary materials 111 provide reliable support.

Wide range of applications: from architecture to art

The wide application of auxiliary material 111 is another highlight. In the construction field, it can be used in various scenarios such as wall reinforcement, ground laying and bridge construction, which significantly improves the safety and durability of buildings. In the manufacturing industry, auxiliary materials 111 are often used as liners or protective layers for machine parts, effectively reducing wear and noise. In terms of artistic creation, artists use their unique texture and plasticity to create refreshing works.

No matter what type of project you need, the auxiliary material 111 is a reliable choice.

The Power of Technology Behind Superior Performance

The reason why the auxiliary materials 111 has such excellent performance is inseparable from the strong scientific research team and cutting-edge technical support behind it. After years of research and development and countless experimental verification, scientists have finally found an ideal formula that perfectly combines the advantages of multiple materials. Not only that, they also introduced a series of innovative processes in the production process, further improving the overall performance of the material.

From microstructure to macro performance, every detail has been carefully designed and repeatedly tested to ensure the stability and reliability of the auxiliary material 111 in practical applications.

Successful Case Analysis: Witness the Miracle

Numerous successful cases have witnessed the magical effect of auxiliary material 111. In a large commercial complex construction project in Shanghai, due to the complex geological conditions, regular building materials can not meet the requirements. The project side decided to use auxiliary material 111 for foundation pit support, which not only shortened the construction period, but also greatly reduced the cost, and the quality of the project was significantly improved.

Another example occurred in the production workshop of a high-tech company. Due to long-term use, mechanical equipment has been severely worn, resulting in a decline in production efficiency. After the technicians tried to use the auxiliary material 111 as a cushion, the problem was solved and the production line resumed efficient operation.

Reasons for selecting auxiliary material 111

The core competitive advantages of auxiliary materials 111 are its excellent cost-benefit ratio, simple and fast construction method, and low post-maintenance costs. Compared with other similar products, the auxiliary material 111 is more cost-effective and can better meet the diverse needs of customers in different industries. At the same time, its easy-to-operate feature also brings great convenience to the site construction.

For professionals looking for efficient and economical solutions, supporting materials 111 is undoubtedly the best choice.

How to use the auxiliary material 111 correctly

In order to help users better play the role of auxiliary material 111, we have compiled a detailed guide for use. First of all, it is necessary to make sufficient preparations, including measuring dimensions and cleaning surfaces. Then install or apply according to the requirements of the instructions, pay attention to evenly distribute the pressure, avoid bubbles or cavities. Finally, the material is fully cured before it is put into use.

Following the above steps, you can enjoy the convenience and advantages of auxiliary material 111 to the maximum.

Environmental Protection and Sustainable Development

In addition to superior performance, the auxiliary material 111 also has a good performance in environmental protection. As a green building material, it has good biodegradability and will not pollute the environment. In addition, clean energy is used in its production process, and its carbon emissions are much lower than traditional building materials, which meets the requirements of modern society for sustainable development.

The choice of auxiliary material 111 is the choice of an earth-friendly lifestyle.

User evaluation and market response