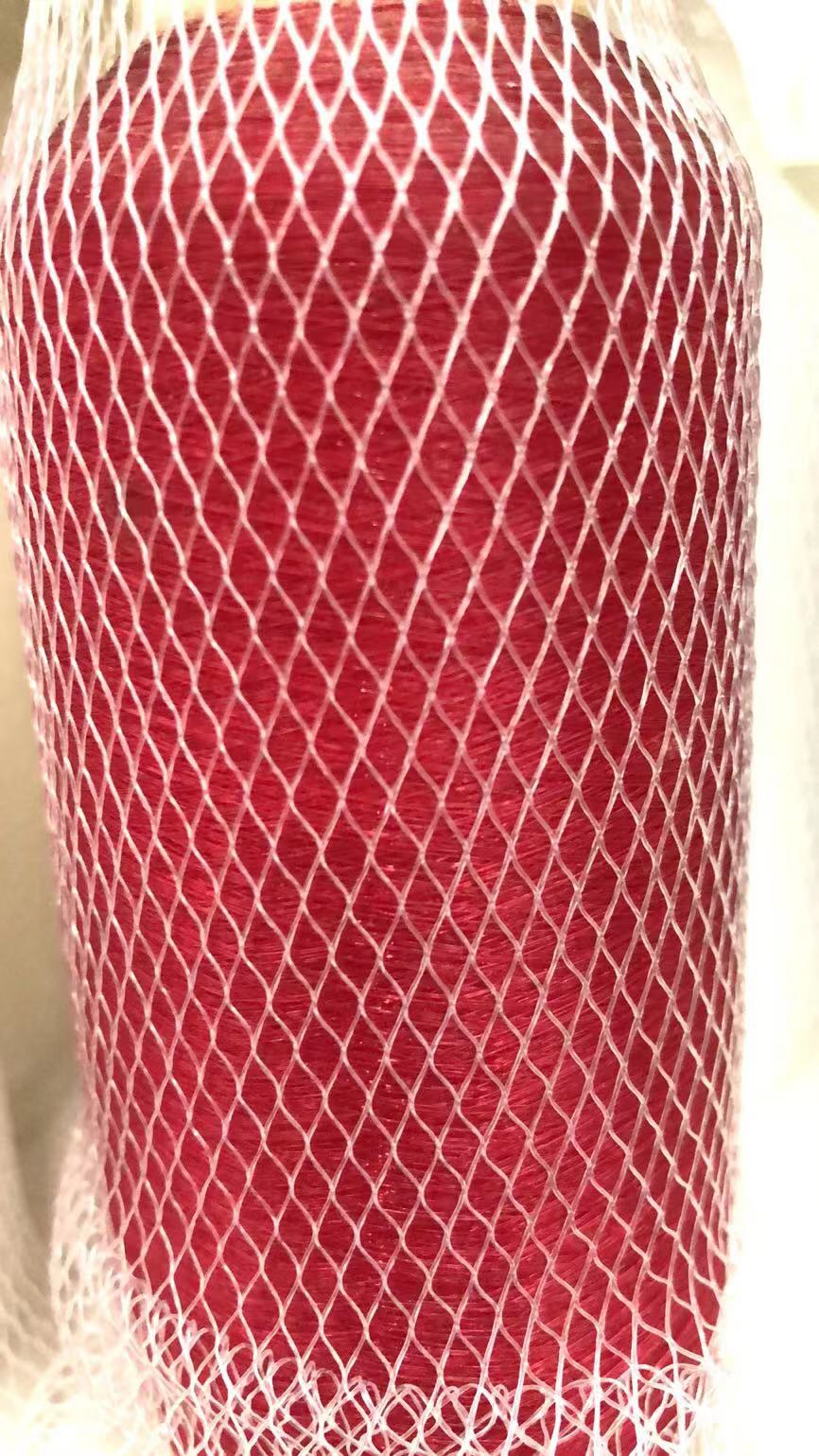

What is auxiliary material 111

Ancillary material 111 is a high-performance material designed for a wide range of manufacturing processes. It is composed of a variety of selected ingredients with excellent physical and chemical properties. What makes this material the secret weapon to improve workmanship? First, it provides excellent stability and consistency in the production process, thus ensuring the high quality of the product. Secondly, its unique formula makes the material perform well in various environments, whether it is high temperature, low temperature or humid conditions, it can maintain stable performance. These properties make the auxiliary material 111 an indispensable choice for many manufacturers.

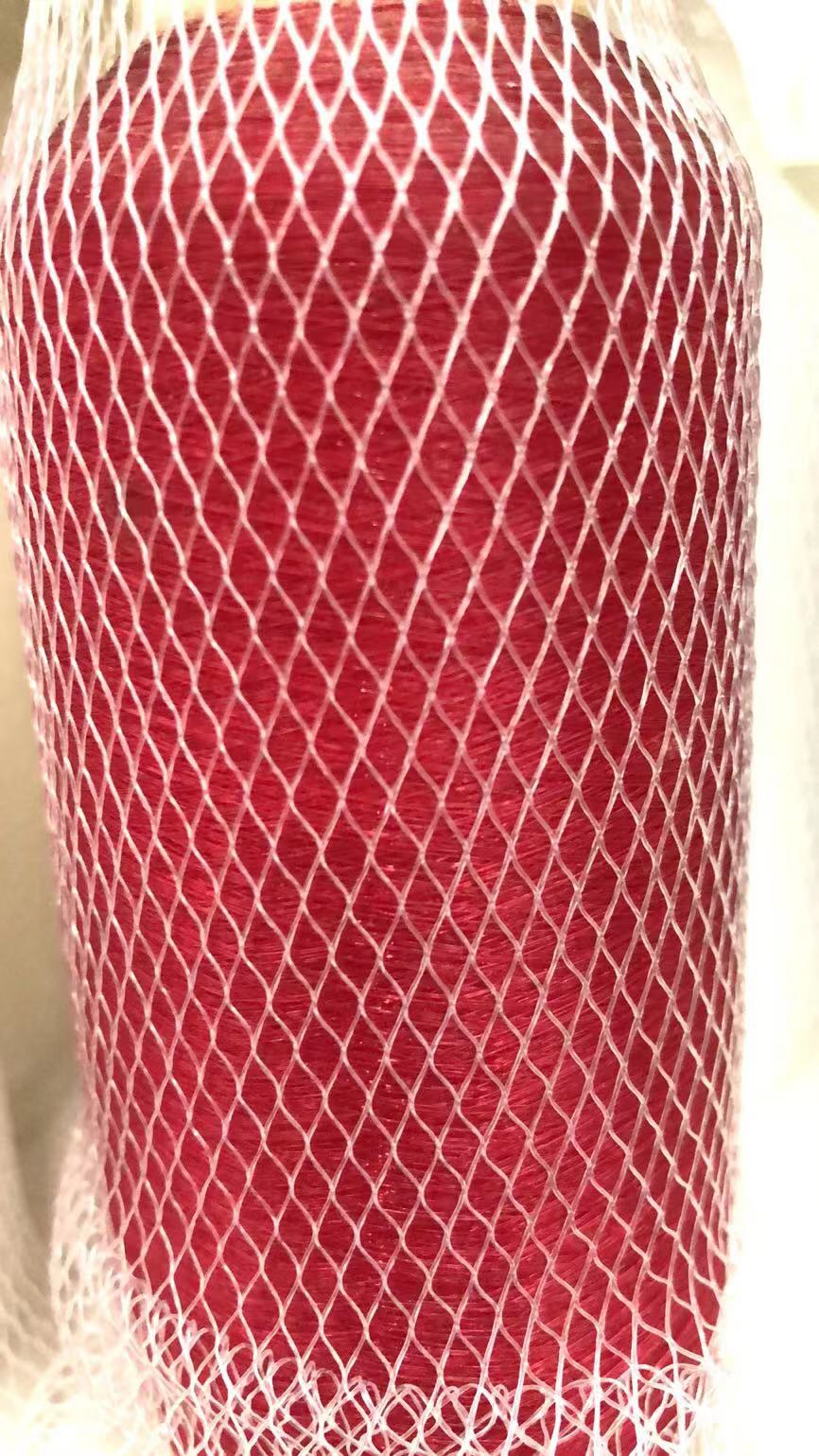

The key to improving product quality

The application of auxiliary material 111 in the production process can significantly improve the quality and stability of products. Through its evenly distributed nature, the material ensures that every component meets a consistent standard. In addition, it can also reduce defects and defects in the production process, thereby improving the pass rate of finished products. For example, in the production of plastic products, auxiliary material 111 can help eliminate bubbles and cracks, making the product surface smooth and flawless. In metal processing, it can improve the fluidity and filling performance of materials, and ensure the precise molding of parts. In short, the addition of auxiliary materials 111 can make the production process smoother and ultimately produce more high quality products.

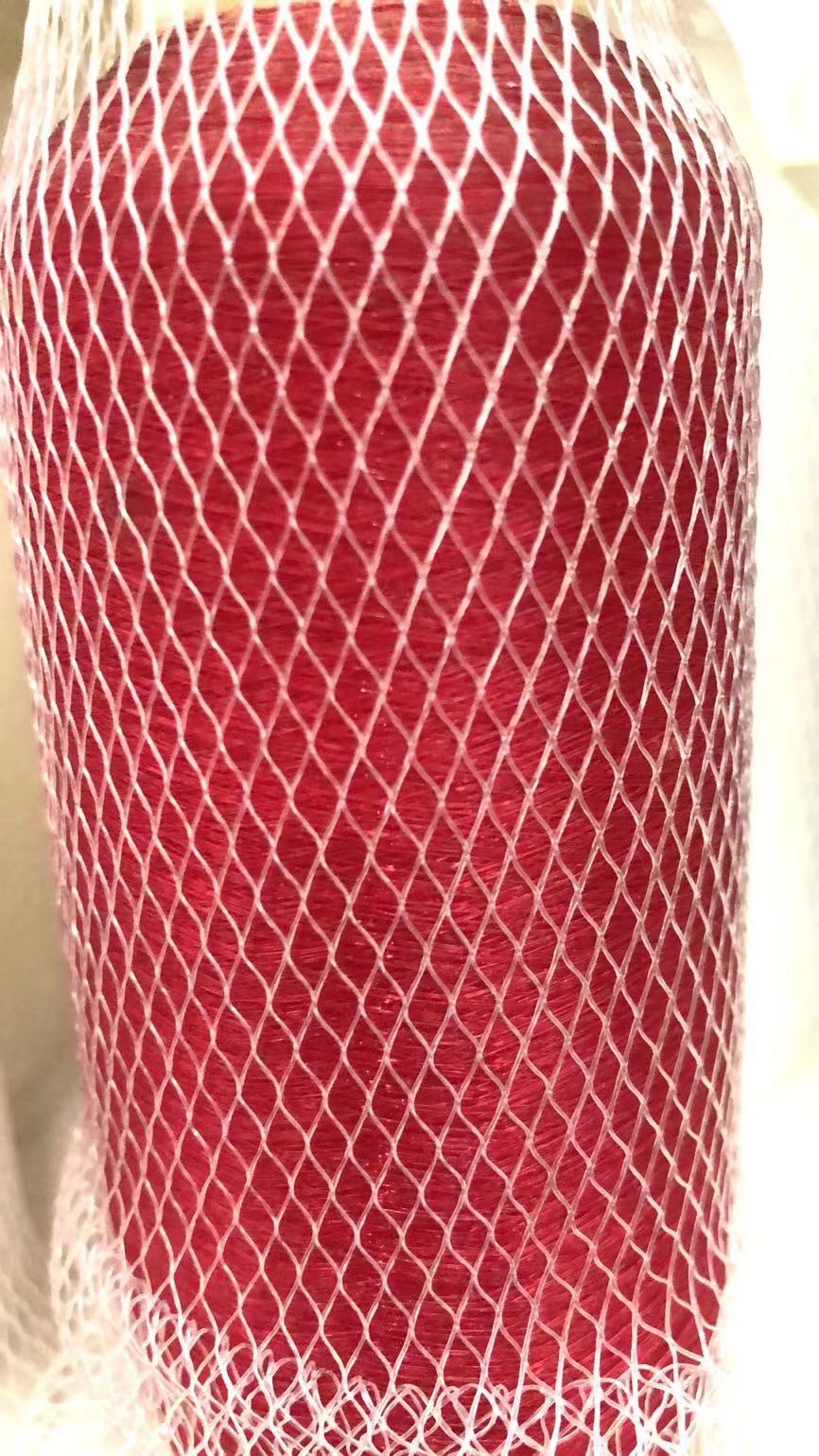

Secrets to Productivity

The 111 of auxiliary materials not only improves the quality of products, but also plays an important role in production efficiency. By reducing processing time and scrap rates, this material can significantly improve the overall efficiency of the production line. For example, in the injection molding process, the auxiliary material 111 can speed up the cooling rate and reduce the residence time of the mold, thereby increasing the production speed. In addition, due to its excellent lubrication performance, the material can reduce the wear of mechanical equipment and extend the service life of the equipment. These advantages make the enterprise more competitive in the competitive market.

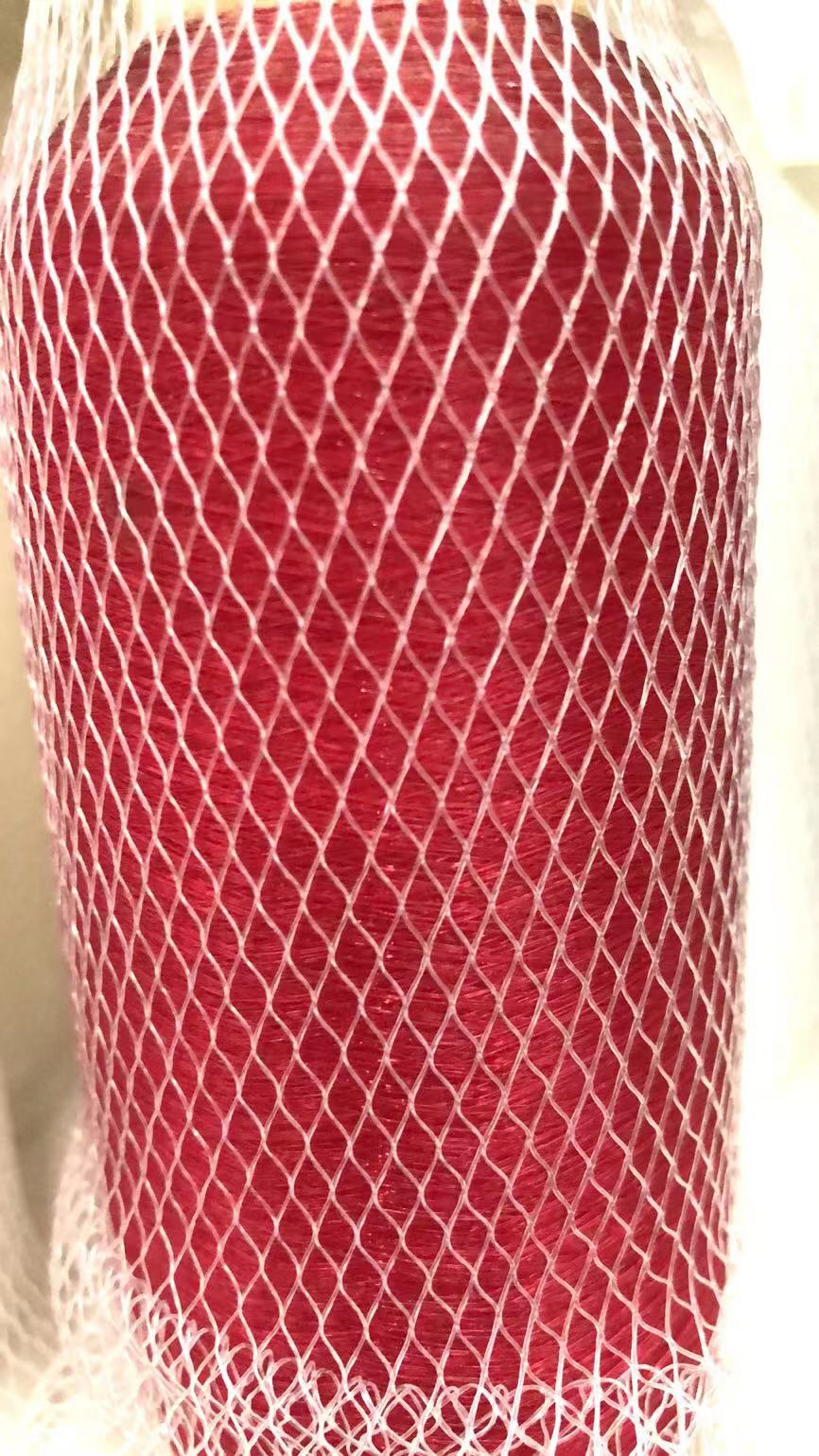

Multi-scenario application instance

The auxiliary materials 111 is not only suitable for a single industry, but also shows excellent performance in many fields. In automobile manufacturing, it is widely used in the production of body parts to improve the strength and durability of parts. In the production of electronic components, the auxiliary material 111 can improve the soldering performance of the circuit board and reduce the virtual soldering phenomenon of the solder joints. In building construction, it is used as a concrete additive to enhance the compressive strength and durability of concrete. These application examples demonstrate the wide applicability and flexibility of the auxiliary material 111.

Customer Success Story

Many companies have achieved a double improvement in product quality and production efficiency through the use of auxiliary material 111. For example, after an automobile manufacturing company introduced auxiliary material 111, the qualified rate of body parts increased by 10%, and the production cycle was shortened by 15%. Another electronics manufacturer also said that since the use of auxiliary material 111, the circuit board welding defect rate has been reduced by 20%. These success stories provide valuable experience and confidence for enterprises to encourage more enterprises to try this high-performance material.

How to select and purchase auxiliary material 111

In order to help potential users find suitable solutions faster, here are some suggestions on how to choose and purchase auxiliary material 111. First of all, according to your specific needs to choose the appropriate specifications and models. Different application scenarios may require materials with different properties. Secondly, it can be purchased through official websites, authorized dealers or professional exhibitions. Finally, pay attention to after-sales service and support, choose brands and suppliers with good reputation, and ensure timely technical support and services during use.

Precautions for maintenance and use

In order to ensure the best performance of auxiliary material 111, correct use and maintenance methods are essential. First of all, the storage conditions should be appropriate, avoid high temperature and humid environment. Secondly, the state of the material should be carefully checked before use to ensure that there is no agglomeration or deterioration. In the process of use, follow the recommend operation steps, regular cleaning and maintenance of the equipment. These measures help to extend the service life of the material and ensure the smooth progress of the production process.

Future Trends

Looking ahead, the auxiliary materials 111 will continue to usher in new development opportunities. With the continuous development of new materials, the performance of auxiliary material 111 will be further improved to meet more complex and demanding application scenarios. The market prospects are broad, especially in the fields of new energy and intelligent manufacturing, and the 111 of auxiliary materials is expected to play a greater role. Enterprises should pay attention to industry dynamics and technological progress in a timely manner, seize future opportunities, and achieve sustainable development.