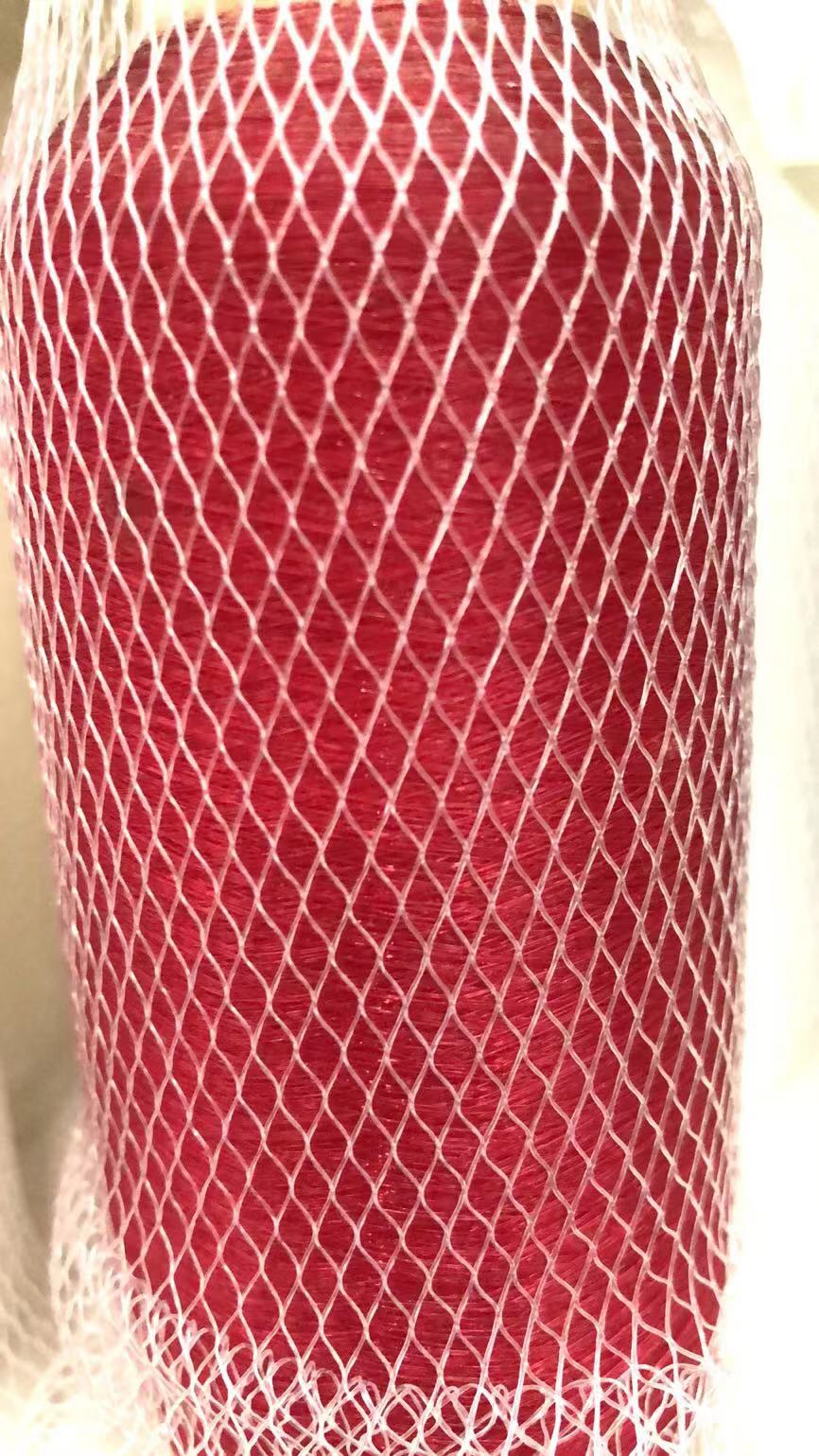

A revolutionary breakthrough in high-performance materials

The auxiliary material 111 has demonstrated its superior performance in many industries.

The auxiliary material 111 has demonstrated its superior performance in many industries.

In recent years, with the progress of science and technology and the change of market demand, more and more enterprises begin to seek more efficient production process solutions. As an innovative material, the auxiliary material 111 has shown excellent performance in this respect. It can not only significantly shorten the processing time, but also significantly reduce the cost of energy consumption, so as to help enterprises achieve green production and sustainable development. Through the specific data comparison analysis and user feedback evaluation, we can deeply understand the innovation brought by this new material.

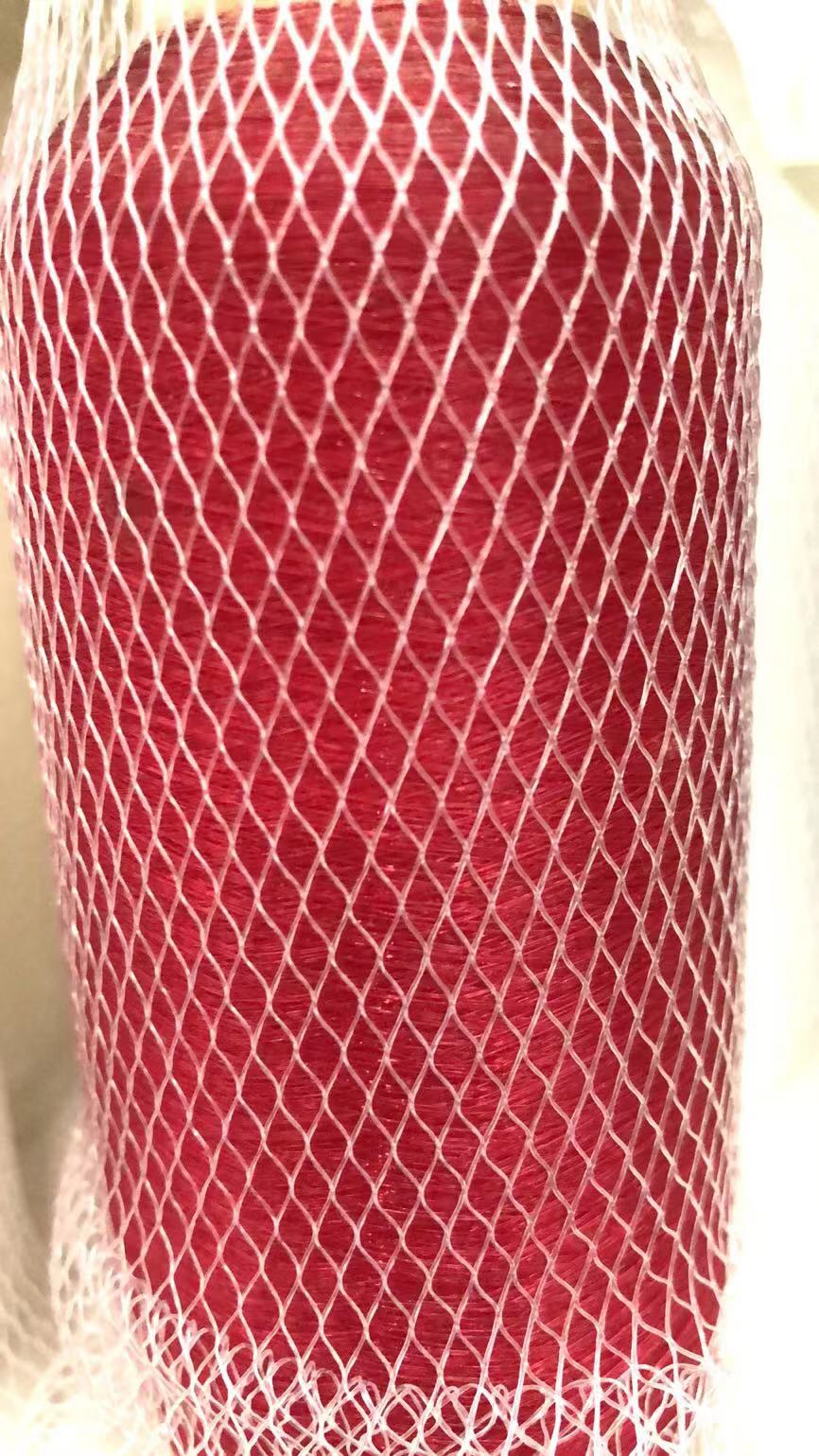

Unlimited possibilities for multi-purpose use

The 111 of auxiliary materials is not limited to a specific industry. In fact, it has been widely recognized and achieved good results in many fields. From manufacturing to construction to electronic equipment manufacturing and other aspects have its figure. For example, adding a small amount of this material in the production process of auto parts can significantly improve the strength of the parts; and when used in concrete additives in construction projects, it can make the building structure more durable. This part of the content will be combined with the actual case detailed analysis of this magic substance is how to maximize the effectiveness of different needs.

Stable performance helps long-term reliable operation

Any new material that wants to gain a foothold in the market must have excellent and stable physical and chemical properties. In this regard, the auxiliary material 111 performance is particularly prominent. After many experimental tests, it has been proved that even in extreme environments (such as high temperature, high humidity, etc.), the material still maintains good stability and is not prone to deformation or aging. This means that products made of this material have a higher service life and lower maintenance frequency, which in turn reduces the total cost of business operations. We will also share stories of customers who have successfully used these features to optimize their production lines.

Simplify processes and improve productivity

In addition to its excellent properties, the introduction of auxiliary material 111 can greatly simplify the existing production process. Because of its easy mixing and rapid curing molding characteristics, in many cases can save the cumbersome manual operation steps, save a lot of manpower and material resources at the same time improve the overall operation speed. Especially in large-scale mass production scenarios can reflect the importance of this point. Next, we will show a few specific examples of how typical factories have achieved output growth through this technological reform, and describe some of the key measures they have taken.

Environmental protection and energy saving create a green future

Modern society pays more and more attention to environmental protection, so choosing green and environmentally friendly raw materials has become one of the consensus of many enterprises. The 111 of auxiliary materials meets this requirement because it shows a relatively low level of carbon emissions throughout the life cycle of production and use. In addition, compared with traditional similar products, it also has a better recycling rate, which helps to reduce waste generation. Through the research and analysis of relevant data, we can see that the use of such advanced materials has a positive significance for promoting the transformation of the entire industrial chain to low carbon. Finally, we will discuss the thinking direction of enterprises in practicing social responsibility.

Innovation-driven market initiative

In the face of an increasingly competitive market environment, only continuous innovation can continue to gain competitive advantage. Many leading companies have begun to realize this and put more energy into the research and development of new technologies and products. This includes efforts to actively explore potential application scenarios 111 auxiliary materials. For example, some high-tech companies are trying to apply it to smart wearable device shell protective layer and other fields, in order to create a more competitive product line. This section aims to encourage readers to pay attention to the development of the industry and stimulate their curiosity and creativity about the future possibilities.