The hero behind the scenes-uncovering the mystery of the 111 of auxiliary materials

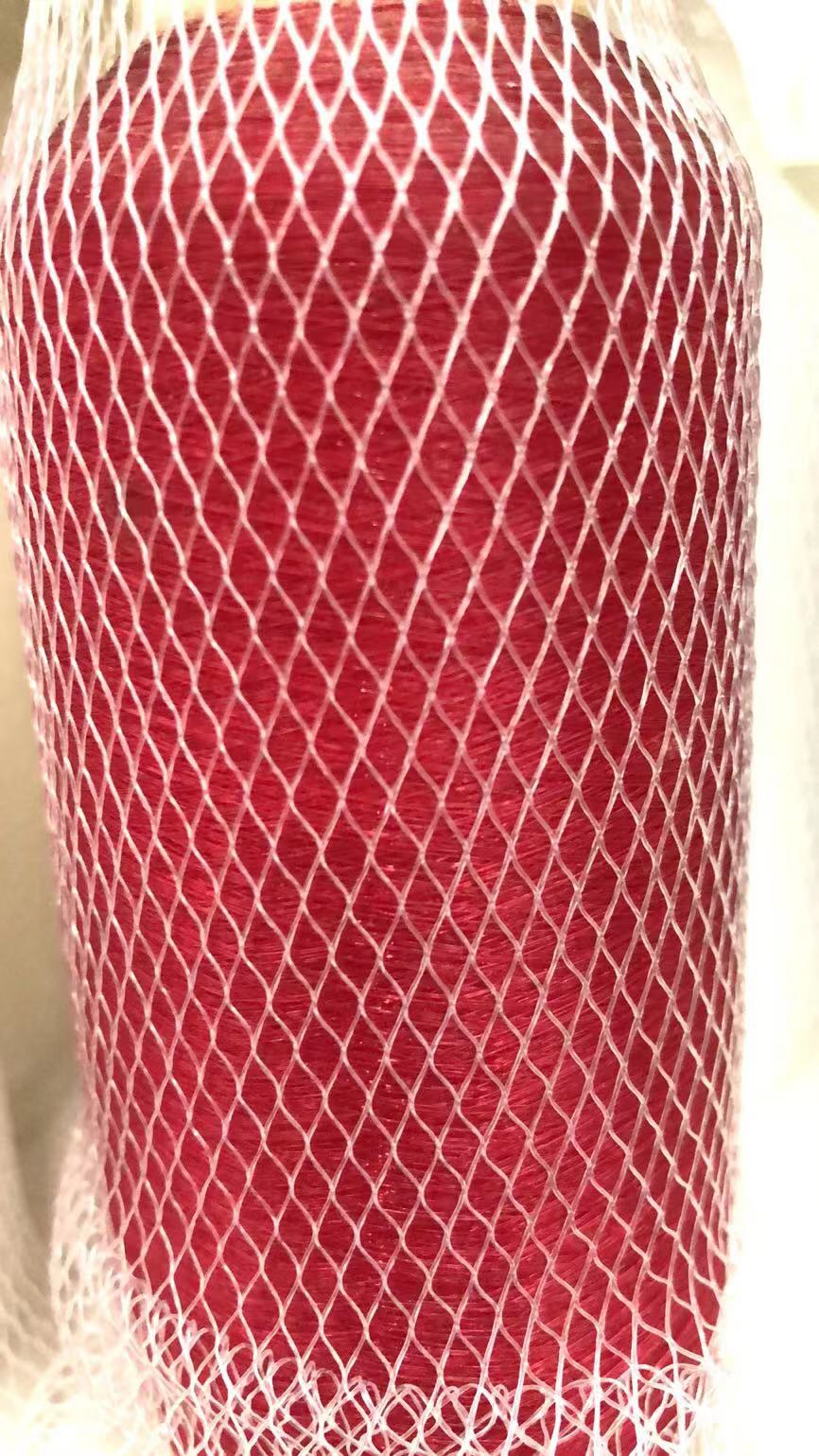

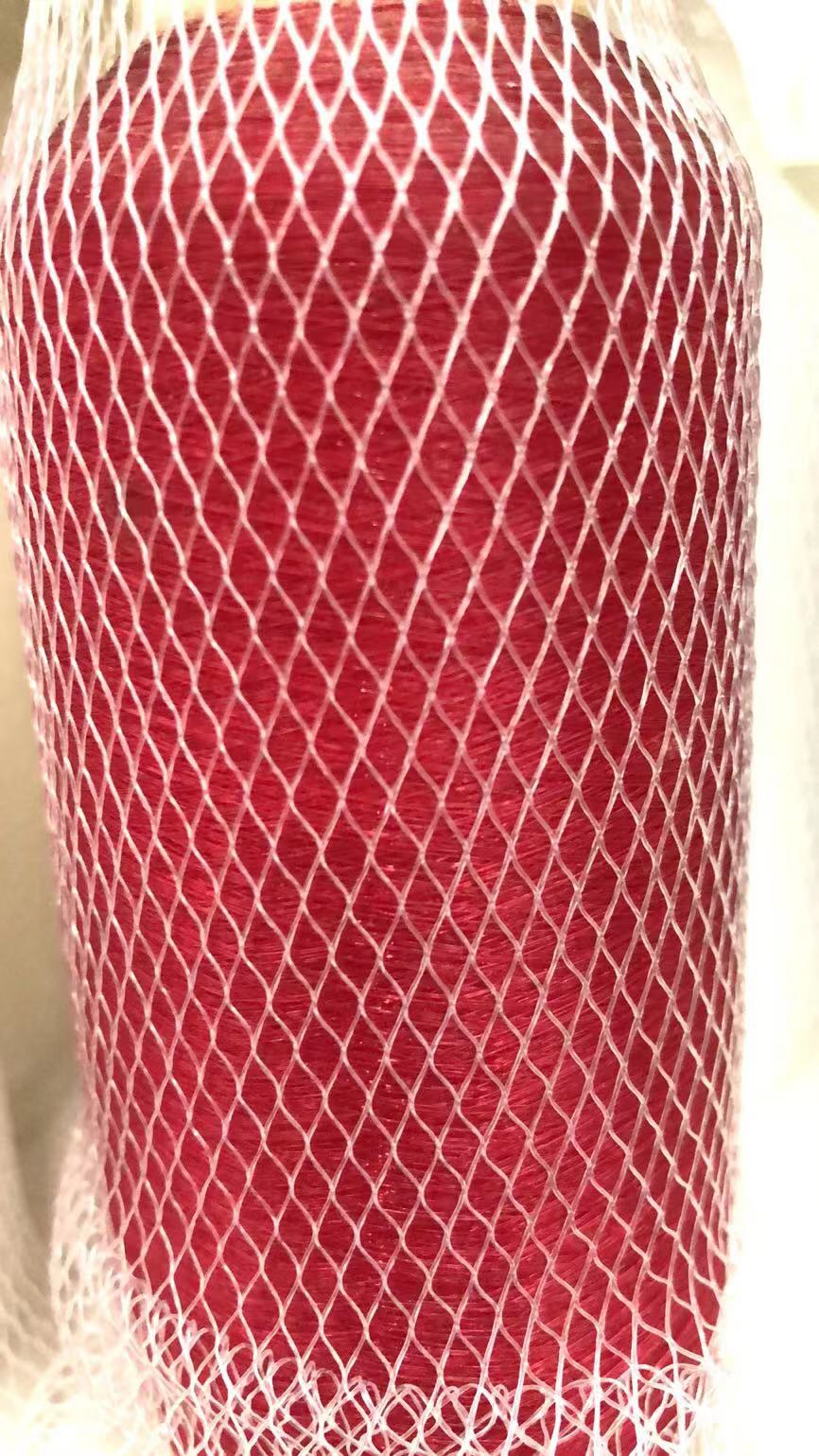

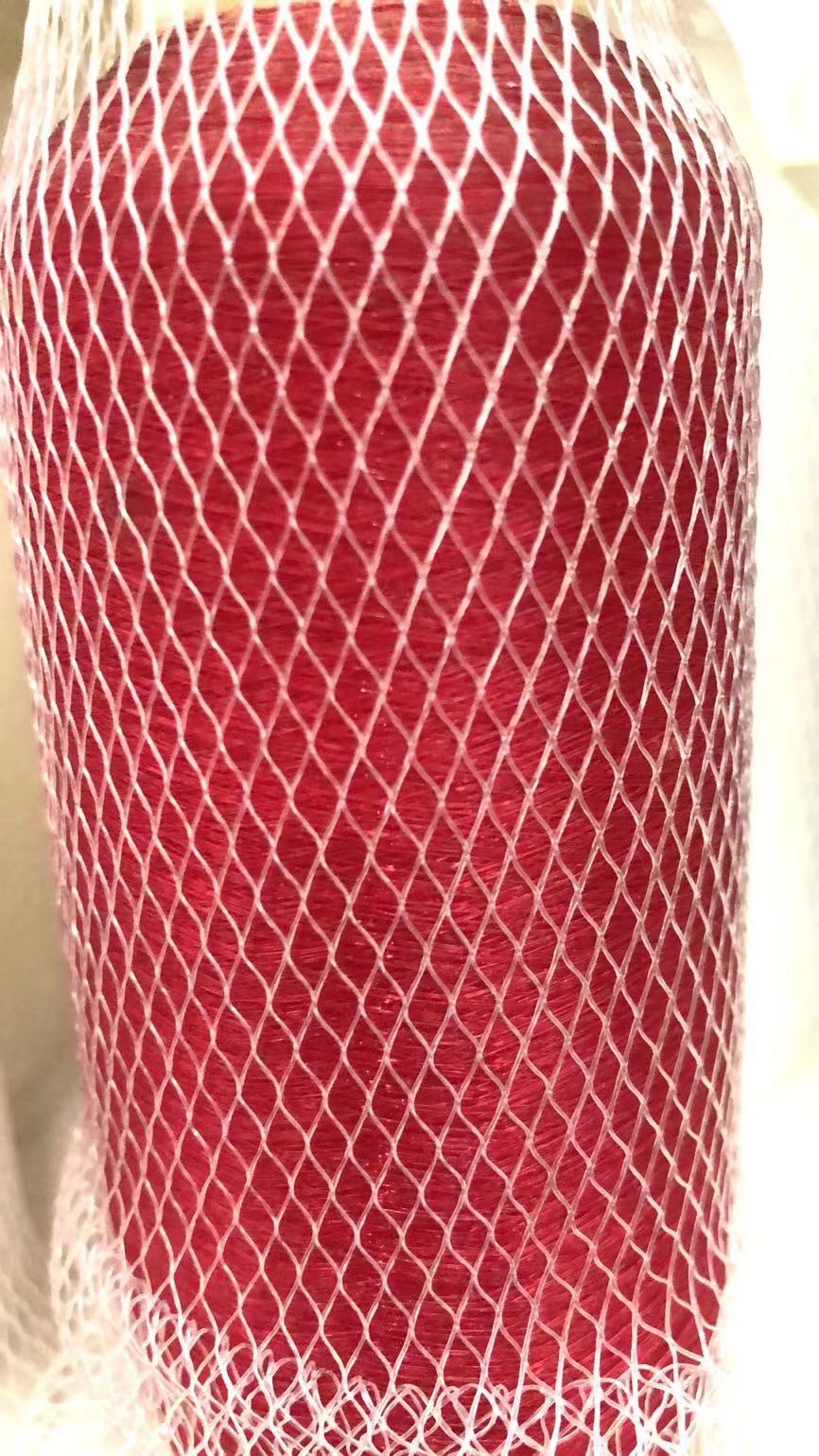

The auxiliary material 111 is a unique composite material that has been carefully developed and quickly emerged with its excellent physical and chemical properties. It is made of a variety of high-performance polymers, with excellent mechanical strength and stability. From the selection of raw materials to the delivery of finished products, every step is carried out under strict quality inspection standards to ensure the consistency and reliability of product quality.

In many engineering projects, supporting materials 111 play a vital role. Whether it is the bridge construction or the foundation support of high-rise buildings, it can be seen. A typical example is that in the construction process of a large commercial complex, this new material is used to replace the traditional reinforced concrete structure, which not only shortens the construction period, but also greatly reduces the maintenance cost. Through this successful case, it can be seen that the 111 of auxiliary materials is gradually becoming an indispensable part of the industry.

Core Advantage-New Choice Beyond Traditional Materials

Ancillary materials 111 exhibit significant technical advantages over other competing products available on the market. First of all, in terms of durability, the material can maintain a stable state for a long time in extreme environments without deformation or aging; secondly, its strong corrosion resistance makes it suitable for complex operating environments in chemical, marine and other fields; Last but equally important, as a green and environmentally friendly material, there is almost no harmful substance emission during production and use, in line with the requirements of modern society for sustainable development.

In order to verify the true effectiveness of the above characteristics, we conducted a large number of laboratory tests and outdoor field trips, and obtained a series of convincing data support. For example, there is no obvious sign of damage after continuous immersion for more than one thousand hours under salt spray test conditions; the surface finish after simulated acid rain erosion has almost no change, and so on. These evidences are sufficient to prove that the auxiliary material 111 does have excellent performance ahead of the same industry.

Application Scenario-A Successful Model with Wide Application in Multiple Fields

With its versatility, auxiliary material 111 has been widely used in various industries. In the field of construction engineering, it can be used to make lightweight prefabricated components, reduce the weight of buildings while enhancing seismic performance; while in manufacturing factories, it is used in key parts of production line conveyor belts and other automation equipment, effectively improving The overall operational efficiency. In addition, transportation infrastructure construction and municipal utilities have also introduced this new product to improve the operation of existing systems.

Here are a few examples of specific implementations:

- construction: in a modern office building construction project, the use of prestressed beam system, the use of high-strength fiber reinforcement technology made of new building materials instead of the original steel frame system, making the whole building more durable and reduce the cost of about 10% or more.

- industrial manufacturing: for an electronic product assembly factory, due to the frequent handling of heavy machine parts, the ground is seriously worn, so a layer of artificial stone floor tiles with a specially customized thickness of about 5cm is laid to solve the problem that has plagued the enterprise for a long time.

- Transportation: The newly-built urban expressway adopts advanced permeable asphalt paving technology and special drainage ditch device to ensure the smooth drainage of rainwater from the road surface, which greatly improves the driving safety factor.

Operations Guide-Easy to Master the Secrets of Efficient Use

In order to enable the majority of users to better understand and apply this new technology, here we will introduce in detail the method of choosing the right specifications and the correct installation process considerations. When faced with different actual needs, please be sure to make reasonable judgment according to the specific situation and refer to the relevant manual to carry out standardized operation.

first of all, the required size and load magnitude should be determined, which depends on the expected use and the importance of the location before making a decision. Secondly, each process task should be carried out in strict accordance with the guidelines in the instructions, including but not limited to the selection of cutting and cutting methods, the design of connecting fixed nodes, etc., and every detail should be meticulously completed; it is also very important to always pay attention to the question of whether personal protective measures are in place to avoid the risk of accidental injury.

for the first contact with such products friends may encounter some of the common problems are given as follows:

-how to identify the authenticity? you can check whether there is a formal manufacturer on the packaging logo and related certification.

-What if you accidentally get dirty? Before cleaning, check whether the detergent composition will damage the material itself before taking action.

-Do you have any special requirements for storage conditions? Try to store in a dry and well-ventilated place away from fire sources to prevent deterioration and damage.

Economic benefits-visible cost savings and revenue growth

Choosing to use auxiliary materials 111 can not only bring direct and considerable financial returns to enterprises, but also indirectly promote the overall improvement of social benefits. According to research, in the long run, compared with ordinary building materials, it can reduce the overall input cost by more than 30% (including the purchase price, transportation and logistics expenses), and at the same time extend the service life by at least twice the length of time because of its excellent quality assurance, so as to realize the purpose of maximizing the use of resources.

In addition to saving money, it is more important to improve production efficiency and service levels. For example, after a batch of brand-new roof insulation panels were replaced during the plant renovation and upgrading plan in an industrial park, the indoor temperature dropped by an average of about 4 degrees Celsius in summer, and the working environment of employees became more comfortable and pleasant, which stimulated higher labor enthusiasm; on the other hand, as the urbanization process continues to accelerate, many old communities are also actively seeking effective solutions to deal with the increasingly severe challenges of domestic waste disposal. At this time, if large-scale promotion and application of such efficient waste recycling and sorting containers will undoubtedly achieve twice the result with half the effort.